SUMMARY

BOS 100® was successfully implemented as part of a combined remedies strategy to treat elevated levels of Trichloroethylene in a shallow fine grained aquifer at a former large industrial facility.

Combined Remedies Treat Large Chlorinated Industrial Site (BOS 100®)

CHALLENGES

A large industrial facility used vapor degreasing in the 1970s and 1980s that resulted in chlorinated volatile organic compound (CVOC) contamination of soil and groundwater. Multiple source areas were discovered and a large plume (greater than 350 feet [ft]) existed on site. In the primary source area (defined as Trichloroethene [TCE] concentrations in groundwater exceeding 50 mg/L)], rapid cleanup with minimal daughter product generation was required. Shallow groundwater occurs in unconsolidated soil (weathered shale and residual silty clay soil derived from shale) and shallow weathered bedrock (fissile shale interlayered with thin beds of siltstone, sandstone, and limestone). Bedrock occurs at relatively shallow depths (5 to 18 ft below ground surface [bgs]) and the depth to groundwater varied from 2 to 5 ft bgs.

APPROACH

In 2010 pilot testing of Trap & Treat BOS 100® demonstrated the ability of the product to effectively and quickly reduce the source area mass and limit the production of CVOC daughter products. Before the full-scale injection event, a Remedial Design Characterization (RDC) was performed. The purpose of the RDC was to fill data gaps and develop a high-density conceptual site model to prepare an accurate remedial design and define the BOS 100® loadings. One hundred twenty-eight soil samples were collected from various horizons (typically every 1-2 ft) and discrete interval micro wells were installed to supplement the existing monitoring well network. Based on this analytical data, provided at no cost by the RPI Quality Assurance Laboratory, an optimized BOS 100® injection strategy was developed and implemented. Enhanced reductive dechlorination (ERD) was selected for treatment of the outlying plume and involved injection of an electron donor, pH buffer, and a dechlorinating bacterial culture. For more information regarding the ERD portion of the work, please contact AST Environmental.

LOCATION

Kentucky

CLIENT

Industrial Facility

SOLUTION

27,510 pounds of BOS 100® injected in the source area on an injection grid that varied from 5 ft to 7.5 ft (triangular grid). The injection interval began at 6 ft bgs and extended to a maximum depth of 3 ft into the weathered shale. Installation in the overburden was performed using traditional direct-push techniques, while specialized methods were used to penetrate and distribute BOS 100® in the weathered shale. The full-scale injections were completed between the fall of 2012 and spring 2014 over the course of two applications.

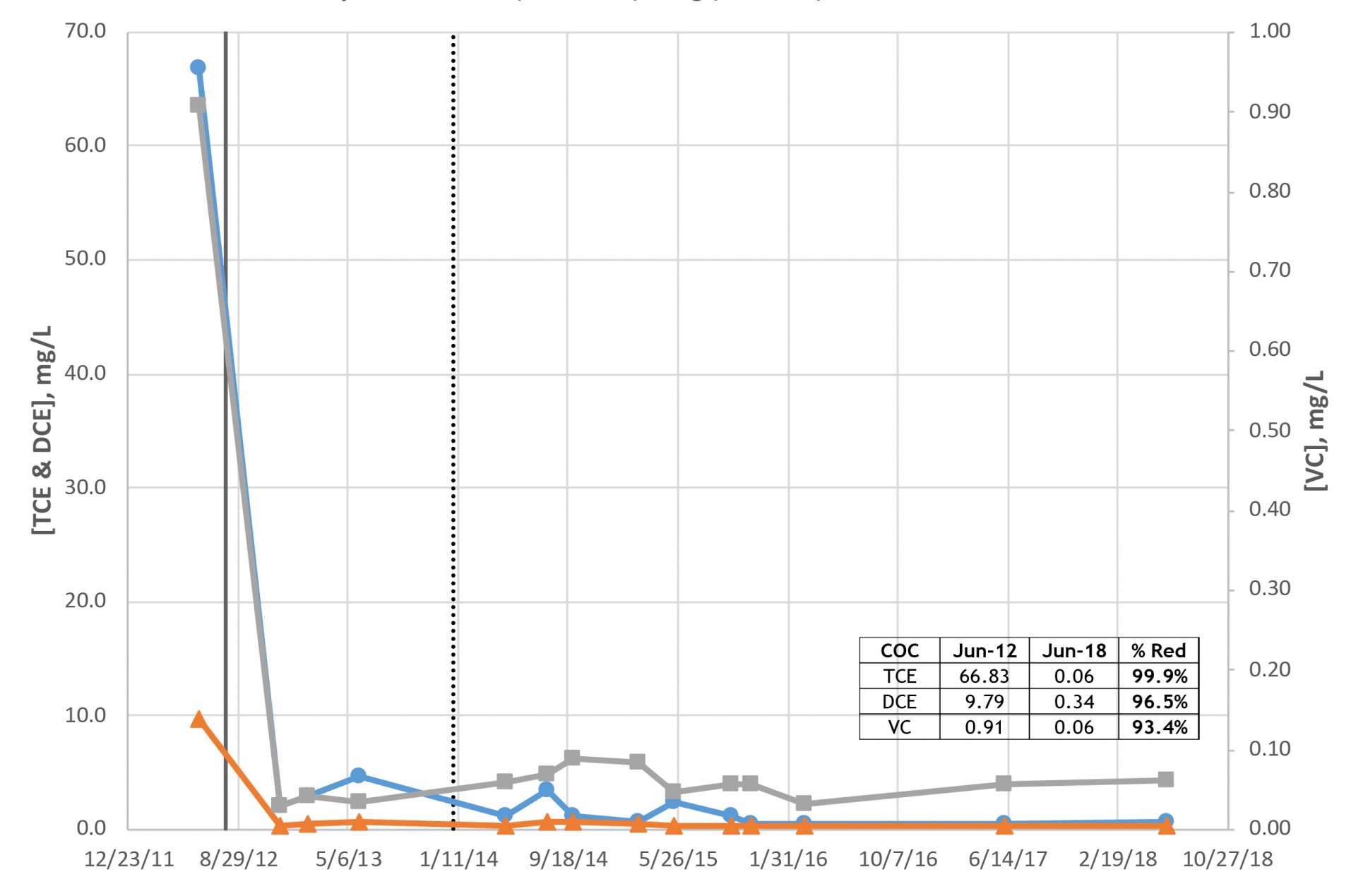

RESULTS

After more than six years in the source areas, reductions of 93.4% to 99.9% have been achieved abiotically using BOS 100®, driving TCE concentrations down from greater than 50 mg/L to less than1 mg/L (with concurrent decreases in daughter products). This approach was successful in reducing the mass of CVOCs in the source areas, and reducing the ongoing mass flux into the less concentrated plume areas.